Beginnings

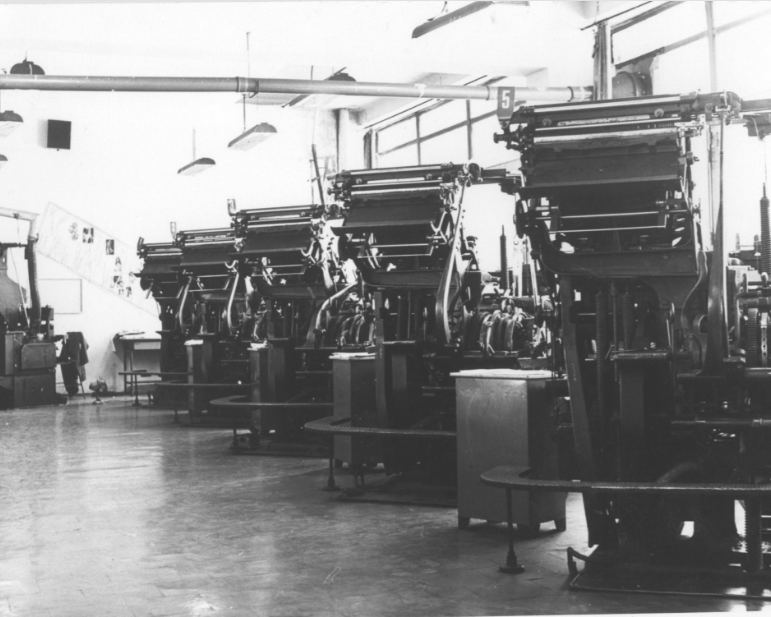

In 1944, on the post-war ruins, a printing house was opened at ul. Malmeda, with a modest equipment of five machines. After 3 years, the printing house already had an organized typesetting department, flat, rotary and lithographic machines, a stereotype and a bookbinding department. These departments were equipped with machines excavated from the rubble and completed by employees and partly imported from other Polish cities. Thanks to the help of printers, the number of fonts has increased tenfold. Most of the production was newspapers among others Jedność Narodowa, Gazeta Białystok (today’s Gazeta Współczesna), Życie Białostockie.

By order of the Minister of Light Industry in 1951, a state-owned enterprise was established under the name Białostockie Zakłady Graficzne.

Change

location

The years 1956-1966 were a time of great development of production, the number of employees also increased. A decision was made to build a new building at 1000-lecia Państwa Polskiego.

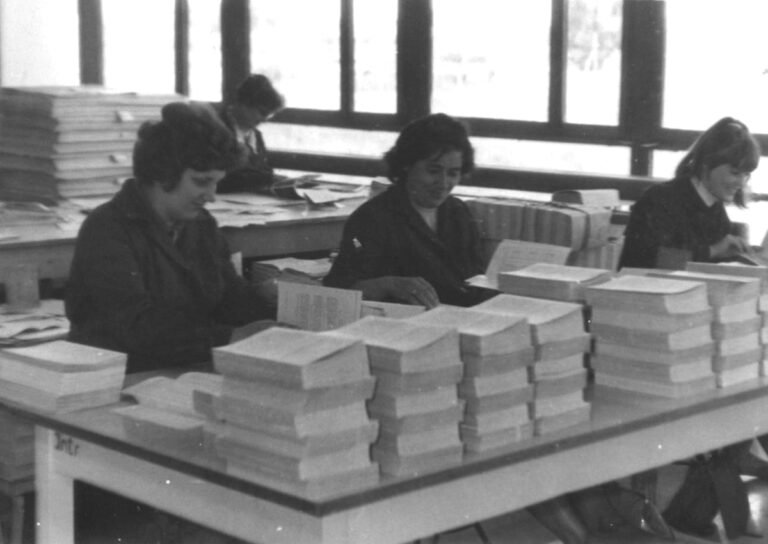

On July 20, 1971, the modern printing house was officially opened. This resulted in even faster development, and less than 4 years later, 625 people worked in Białostockie Zakłady Graficzne. The plant has become an important place in the city space. Employees joined various interest groups and engaged in social initiatives.

There was a volleyball court in the square in front of the building.

Revolution

in assembly, printing

and binding

Until 1993, newspapers were printed. With the end of newspaper printing, work on linotypes was also completed. One of these unusual and historic machines is located in the building of the printing house to this day. It was a breakthrough moment in the printing industry, because there was a complete change in technology, the manual prepress was replaced with a digital one.

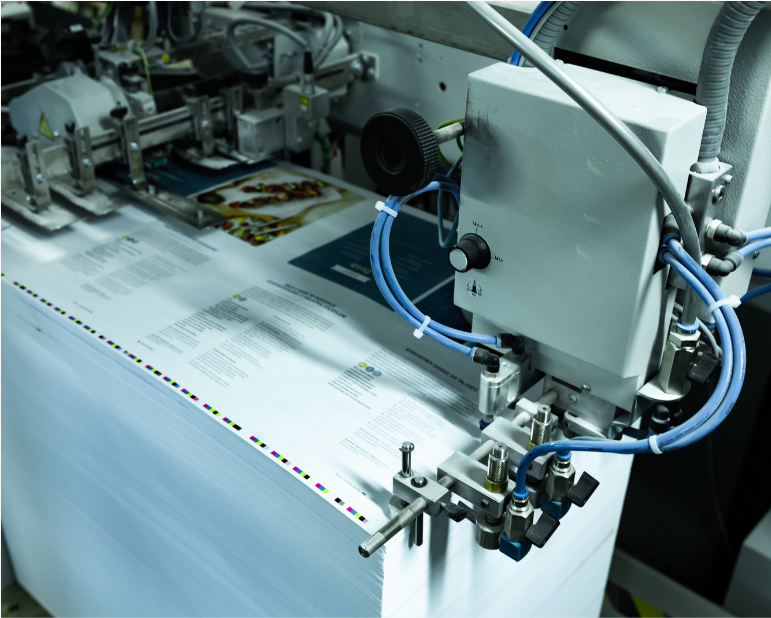

In order to keep up with the client’s expectations, machines using innovative technologies were purchased, such as: Zircon, two Rolands with numbering, Rapida 104 and Rapida 105 and a new line for hard cover binding,

then the Sigloch-BF511 line, and then BF513, a line for perfect binding KM 470. In 2000, investments were made in a Triton tripod by Kolbus, a Stahl cover assembly machine, then DA, a Kolbus foil stamping machine, and a SAB flexibound cover assembly device. To this day, we are one of the few printing houses offering the production of books in flexibound binding.

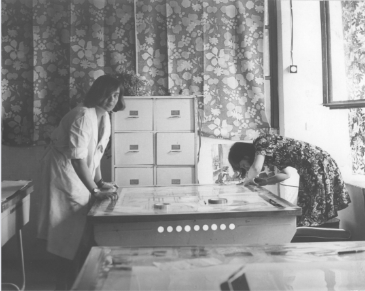

Along with the investment in new machines, it was necessary to retrain the employees. The previous manual typesetting was changed to digital.

This was significant progress and a huge challenge.

For the celebration of the 65th anniversary of BZGraf, we commissioned a new offset full-format sheetfed printing machine Heidelberg Speedmaster SM 102-8-P5 with perfecting, richly equipped with modules of the production management system – Prinect, as well as a digital prepress based on a full-format CtP thermal imagesetter – Suprasetter H105 from Heidelberg.

Privatization

By the decision of the Minister of Treasury, on April 19, 2011, Białostockie Zakłady Graficzne S.A. was sold to a company that is part of the Kompap S.A. Capital Group.

The new owner, Mr. Waldemar Lipka, appointed the Management Board, and then Mrs. Antonina Kuchlewska as the president of the company.

The changes carried out by the new owner and the Management Board brought measurable benefits. The position of BZGraf S.A. was strengthened on Polish and foreign publishing markets. We have rebuilt our position in the printing industry and have been appreciated for quality, punctuality and honest approach to the customer. In 2015, we received the title of “Printing House of the Year” in the 14th Ranking of Polish Printing Houses.

Contemporary

Times

Our story does not end there, we keep investing in more and more advanced machines. Recently, we commissioned a new CtP studio with a Speedmaster imagesetter, and also purchased a Multiplex gathering and stitching line, a full-format MBO K32 folding machine and a KM 600 perfect binding line. We replaced the printing press by installing an eight-color R106 machine, a 2-unit SM2 R105 machine and a 4-unit R105 machine.